Hanyar sarrafa carbon da aka kunna yawanci ta ƙunshi carbonization wanda ke biyo baya kunna kayan carbonaceous daga asalin kayan lambu.Carbonization magani ne mai zafi a 400-800 ° C wanda ke juyar da albarkatun ƙasa zuwa carbon ta hanyar rage abun ciki na al'amura masu canzawa da haɓaka abun cikin carbon na kayan.Wannan yana ƙara ƙarfin kayan aiki kuma yana haifar da tsari mai ɓarna na farko wanda ya zama dole idan ana son kunna carbon.Daidaita yanayin carbonization na iya shafar samfurin ƙarshe sosai.Ƙara yawan zafin jiki na carbonization yana ƙaruwa, amma a lokaci guda yana rage girman pores.Wannan raguwar ƙarar pores shine saboda haɓakar haɓakar kayan abu a yanayin zafi mafi girma na carbonization wanda ke haifar da haɓakar ƙarfin injiniya.Sabili da haka, ya zama mahimmanci don zaɓar madaidaicin tsarin zafin jiki bisa ga samfurin da ake so na carbonization.

Wadannan oxides suna bazuwa daga cikin carbon wanda ke haifar da iskar gas na wani ɓangare wanda ke buɗe pores waɗanda aka rufe a baya kuma suna haɓaka tsarin porous na ciki na carbons.A cikin kunna sinadarai, ana mayar da carbon a yanayin zafi mai zafi tare da wakili mai bushewa wanda ke kawar da yawancin hydrogen da oxygen daga tsarin carbon.Kunna sinadarai sau da yawa yana haɗuwa da carbonization da matakin kunnawa, amma waɗannan matakan biyu na iya faruwa daban dangane da tsarin.An samo wurare masu tsayi fiye da 3,000 m2 / g lokacin amfani da KOH azaman wakili mai kunna sinadarai.

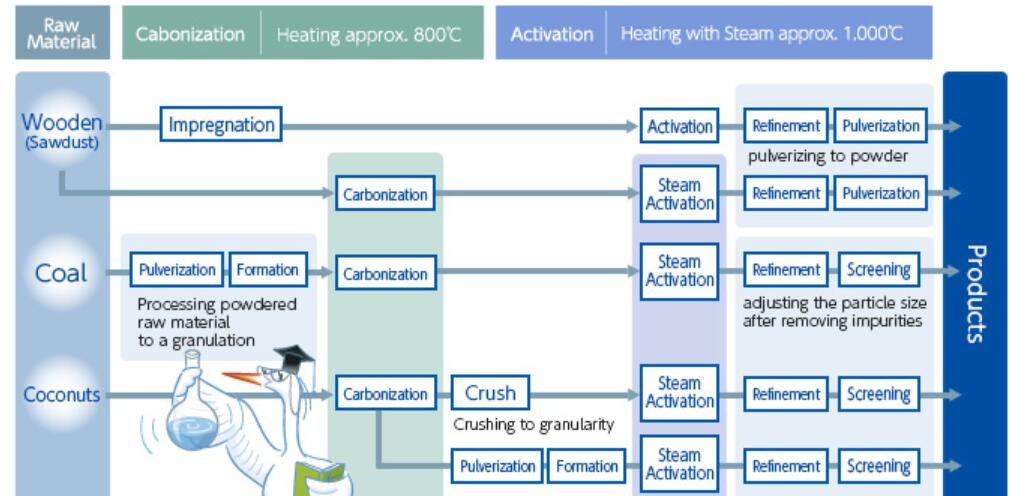

Carbon Mai Kunnawa Daga Kayan Raw Daban-daban.

Baya ga kasancewa adsorbent da ake amfani da shi don dalilai daban-daban, ana iya samar da carbon da aka kunna daga ɗimbin albarkatun albarkatu daban-daban, yana mai da shi samfuri mai ban mamaki wanda za'a iya samarwa a wurare daban-daban dangane da abin da ake samu.Wasu daga cikin waɗannan kayan sun haɗa da harsashi na shuke-shuke, duwatsun 'ya'yan itace, kayan itace, kwalta, carbides na karfe, carbon baƙar fata, zubar da shara daga najasa, da tarkacen polymer.Daban-daban na kwal, wanda ya riga ya wanzu a cikin nau'i na carbonaceous 5 tare da tsarin pore mai tasowa, ana iya ƙara sarrafa shi don ƙirƙirar carbon da aka kunna.Ko da yake ana iya samar da carbon da aka kunna daga kusan kowane ɗanyen abu, yana da tasiri mafi tsada da kuma kula da muhalli don samar da carbon da aka kunna daga kayan sharar gida.Abubuwan da aka kunna na carbon da aka samar daga bawoyin kwakwa an nuna suna da babban adadin micropores, yana mai da su kayan da aka fi amfani da su don aikace-aikace inda ake buƙatar ƙarfin talla.Sawdust da sauran kayan tarkace na itace suma sun ƙunshi ƙwararrun sifofi masu ƙarfi waɗanda ke da kyau don haɓakawa daga lokacin iskar gas.Samar da carbon da aka kunna daga zaitun, plum, apricot, da duwatsun peach suna haifar da adsorbents masu kama da juna tare da tauri mai mahimmanci, juriya ga abrasion da babban ƙarar micropore.Za a iya kunna tarkacen PVC idan an cire HCl a gaba, kuma yana haifar da carbon da aka kunna wanda shine mai kyau adsorbent ga methylene blue.Har ma an samar da carbon da aka kunna daga tarkacen taya.Don bambance tsakanin faffadan kewayon yuwuwar abubuwan da suka faru, ya zama dole don kimanta abubuwan da aka haifar na zahiri bayan kunnawa.Lokacin zabar precursor waɗannan kaddarorin suna da mahimmanci: ƙayyadaddun yanki na yanki na pores, ƙarar pore da rarraba ƙarar ƙura, abun da ke ciki da girman granules, da tsarin sinadarai / yanayin farfajiyar carbon.

Zaɓin madaidaicin madaidaicin aikace-aikacen da ya dace yana da mahimmanci sosai saboda bambancin kayan da aka riga aka yi don sarrafa tsarin pore na carbons.Maɓalli daban-daban sun ƙunshi nau'ikan macropores daban-daban (> 50 nm,) waɗanda 6 ke ƙayyade aikin su.Wadannan macropores ba su da tasiri don adsorption, amma kasancewar su yana ba da damar ƙarin tashoshi don ƙirƙirar micropores yayin kunnawa.Bugu da ƙari, macropores suna ba da ƙarin hanyoyi don ƙwayoyin adsorbate don isa ga micropores yayin tallatawa.

Lokacin aikawa: Afrilu-01-2022