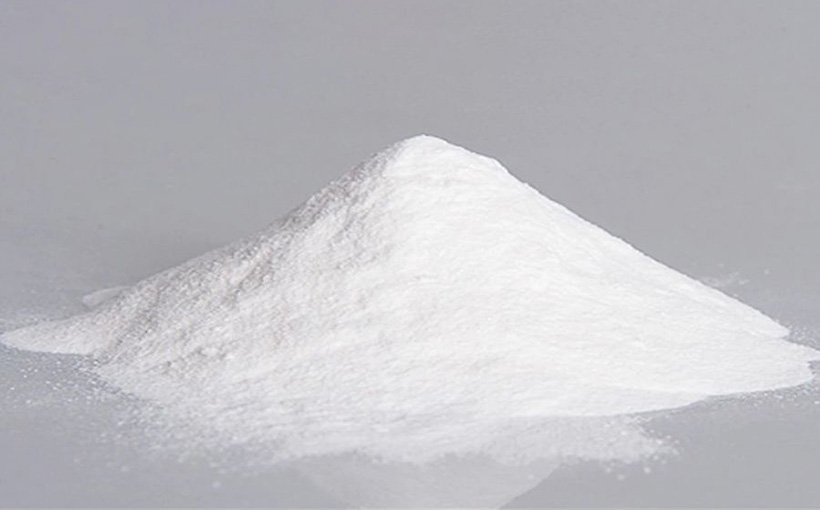

A cikin turmi da aka shirya, ƙari na ether cellulose yana da ƙasa sosai, amma yana iya inganta aikin rigar turmi, wanda shine babban abin da ke shafar aikin ginin turmi.Muhimmiyar rawar da HPMC ke takawa a cikin turmi ya fi yawa a fannoni uku, ɗaya shine kyakkyawan ƙarfin riƙe ruwa, na biyu shine tasiri akan daidaiton turmi, na uku kuma shine hulɗa da siminti.

1. Mafi girman danko na ether cellulose, mafi kyawun aikin riƙewar ruwa.

2. Mafi girman adadin adadin ether cellulose a cikin turmi, mafi kyawun aikin riƙewar ruwa.

3. Don girman ƙwayar cuta, mafi kyawun ƙwayar, mafi kyawun riƙewar ruwa.

4. Ruwan ruwa na methyl cellulose ether yana raguwa tare da karuwar yawan zafin jiki.

A thickening sakamako na hydroxypropyl methyl cellulose a matsayin thickener yana da alaka da barbashi size, danko da kuma gyara na hydroxypropyl methyl cellulose.Gabaɗaya magana, mafi girman danko na ether cellulose, ƙarami girman barbashi, mafi bayyane tasirin sakamako mai kauri.

Matsayi na uku na ethers cellulose shine jinkirta tsarin samar da ruwa na siminti.Cellulose ethers suna ba da turmi kaddarorin masu fa'ida iri-iri sannan kuma suna rage saurin sakin siminti mai zafi da jinkirin aikin samar da ruwa na siminti.Mafi girman ƙaddamar da ether cellulose a cikin kayan gel na ma'adinai, mafi mahimmancin sakamako na jinkirin jinkiri.Cellulose ethers ba kawai jinkirta saitin ba, amma kuma yana jinkirta aiwatar da tsarin tsarin turmi siminti.Tare da haɓakar maganin HPMC, lokacin saita turmi ya ƙaru sosai.

A taƙaice, a cikin shirye-shiryen da aka haɗa turmi, HPMC tana taka rawar riƙewar ruwa, kauri, jinkirta ƙarfin hydration na siminti da haɓaka aikin gini.Kyakkyawan ikon riƙe ruwa yana sa hydration ɗin siminti ya zama cikakke, wanda zai iya inganta jigon jika na turmi da ƙara ƙarfin haɗin turmi.Don haka, ana amfani da HPMC sosai azaman ƙari mai mahimmanci a cikin turmi da aka gama shiryawa.

Lokacin aikawa: Janairu-20-2022