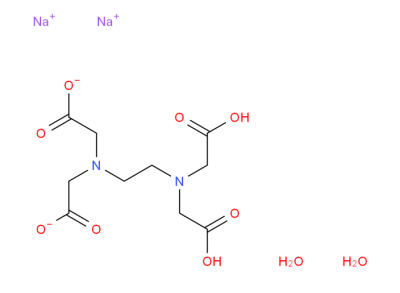

Disodium na Ethylene Diamine Tetraacetic Acid (EDTA Na2)

Bayani dalla-dalla:

| Abu | Daidaitacce |

| Bayyanar | Foda Fari |

| Gwaji (C)10H14N2O8Na2.2H2O) | ≥99.0% |

| Plumbum (Pb) | ≤0.0005% |

| Ferrum(Fe) | ≤0.001% |

| Chloride (Cl) | ≤0.05% |

| Sulfate (SO2)4) | ≤0.05% |

| PH(50g/L; 25℃) | 4.0-6.0 |

| Girman Ƙwayoyin Cuku | <40rag≥98.0% |

Aikace-aikace:

EDTA 2NA muhimmin wakili ne na haɗa ions na ƙarfe da raba ƙarfe. Ana amfani da wannan samfurin a matsayin maganin gyara bleaching don haɓaka da sarrafa kayan ɗaukar hoto masu launi, da kuma ƙarin rini, wakilin maganin zare, ƙarin kayan kwalliya, magani, abinci, samar da ƙwayoyin halitta na sinadarai na noma, maganin hana zubar jini, wakilin haɗa bleaching, sabulun wanki, mai daidaita, robar roba, mai fara polymerization da wakilin nazarin adadi na ƙarfe mai nauyi, da sauransu. A cikin tsarin fara rage chlorine don polymerization na SBR, ana amfani da disodium EDTA a matsayin wani ɓangare na wakili mai aiki, galibi don haɗa ions na ƙarfe da kuma sarrafa yawan amsawar polymerization.

Tsarin Samarwa:

1. A hankali a zuba hadin sodium cyanide da formaldehyde a cikin ruwan ethylenediamine a wani rabo, sannan a wuce iska a zafin 85℃ a karkashin matsin lamba mai raguwa don cire iskar ammonia. Bayan amsawar, a daidaita darajar Ph zuwa 4.5 tare da sinadarin sulfuric mai yawa, sannan a canza launin, a tace, a tattara, a raba shi, sannan a bushe don samun samfurin da aka gama.

2. A haɗa kilogiram 100 na chloroacetic acid, kilogiram 100 na kankara da kilogiram 135 na maganin NaOH 30%, a ƙara kilogiram 18 na ethylenediamine 83% ~ 84% a yayin juyawa, sannan a ajiye shi a 15℃ na tsawon awa 1. A hankali a zuba maganin NaOH 30% a cikin rukuni har sai mai amsawa ya zama alkaline, sannan a ajiye shi a zafin ɗaki na tsawon awanni 12. A dumama zuwa 90℃, a ƙara carbon da aka kunna don canza launin. Ana daidaita tacewa zuwa 4.5 Ph tare da hydrochloric acid kuma a tattara a tace a 90℃; ana sanyaya tacewa, a tace ta, a raba ta a wanke, sannan a busar da ita a 70℃ don samun samfurin da aka gama.

3. An yi shi ta hanyar aikin maganin ethylenediaminetetraacetic acid da sodium hydroxide: A cikin kwalbar amsawa mai lita 2 wanda aka sanya masa abin juyawa, a zuba ethylenediaminetetraacetic acid 292g da ruwa lita 1.2. A zuba 200mL na maganin sodium hydroxide 30% a lokacin da ake juyawa sannan a dafa har sai dukkan martanin sun kammala. A zuba 20% hydrochloric acid a rage zafi zuwa pH = 4.5, a dumama zuwa 90℃ sannan a tace, a tace. A sanyaya tacewa sannan a fitar da lu'ulu'u. A cire a raba, a wanke da ruwan da aka tace, a bushe a zafin 70℃, sannan a sami EDTA 2NA.

4. A zuba ethylenediaminetetraacetic acid da ruwa a cikin tankin amsawar da aka yi da enamel, a zuba maganin sodium hydroxide a lokacin da ake juyawa, a dafa har sai ya yi aiki, a zuba hydrochloric acid zuwa pH 4.5, a dafa zuwa 90°C sannan a tace, a tace, sai a sanyaya tacewar, a tace lu'ulu'un, a wanke da ruwa, a busar da su a zafin 70°C, sannan a sami EDTA 2NA.